For some random reason I decided to make a useless jug.

I wanted it to be a challenge to pick up due to a strangely shaped handle, and just in case someone fancied using it as a jug or a vase, I put holes all the way down the back to make it totally leak if water was added.

Why? No idea. Just a strange idea.

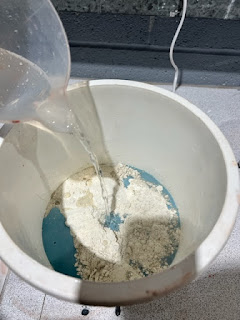

Anyway… I hand build it using rolled out slabs of clay.

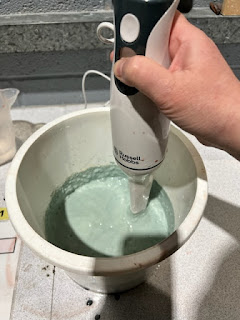

I then painted it in a few coats of different coloured slips.

Can’t even remember what colours I used as I was just grabbing

anything from the cupboard, so it will be a nice (or not) surprise when it

comes out of the kiln.

I decided to do some random designs on it too with my

Sgraffito carving tool. I marked off

some sections to begin…

… then lightly marked a pattern so I could go back and carve it properly once done.

.jpg)