We were learning how to use silicon casting material today

to take a nice detailed cast of items – which can then be made into wax and

finally glass.

So, I thought I would do my hand, complete with jewellery to

see how much detail I could get.

So I plunged my hand into the bucket and waited a little

while for it to set – then after a slight wriggle or two, I was free!

The next step was to pour melted wax into the mould, and

wait for that to harden.

Once the wax was set I could

break away the silicon mould – I then set the waxy hand on a lump of clay to

form a base.

Plaster Recipe for refractory mould: (to be measured up as required)

·

1lb plaster powder

·

1lb molochite powder

·

1 pint water

Now it was time to cover the hand

in the plaster mix. Adding layers at a

time to ensure all the parts were covered.

When the mould was dry, it was time to scrape out the clay and melt out the wax.

This was done over a steamer,

allowing the wax to drip into a tray which meant it could be reused.

Once the wax was out I have

to fill the mould with water to measure how much glass I would need (2.5 x the amount of water)

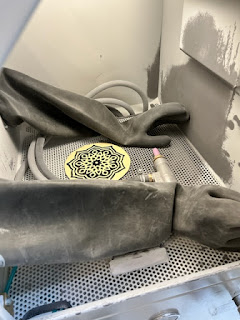

The mould was then put into

the drying cupboard.

Once dry, I filled a

terracotta plant pot with the correct amount of glass and they went into the

kiln.

The mould was positioned with

a table above made from kiln props, on this sat a plant pot with my measured

amount of glass in it. Once the glass melted

it dripped through the hole in the plant pot down into the mould.

I used some scrap glass from

the HotShop to make this as I fancied a little colour.

Now it was time to very carefully chip away the mould, making

sure not to damage the glass inside.

Dah da! A lovely glass hand …. minus a little

pinkie 😊

It was at this point that I realised I had not added any cocktail sticks to help air and glass flow – lesson learnt.

The silicon mould doesn’t last

long and is not really reusable over time, but I managed to get another wax

cast from it.

This piece didn’t need any

coldworking at all, I purposely underestimated the glass amount needed so I didn’t

have much (or any) overspill, and it all came out quite smooth.

.jpg)

.jpg)