Today I had a play some alginate, in the hope of making a plaster hand to hold a light bulb!

I mixed it up according to the instructions, poured it into

a suitably sized container and stuck my hand in it.

It set in about 5 minutes,

but it’s quite hard to keep your hand still for that long… I am not the most

patient person.

It took a little wiggling to get my hand free, but eventually it popped out leaving a nice hole to cast into.

The colour had also changed from pink to white during the process, this is something to do with the setting process.

I filled the hole with a

plaster mix of 1lb of plaster to 1 pint of water.

Then I left it alone for a little while for it to set. The alginate had turned back to pink again at the point.

The next job was to remove the alginate from the plaster.

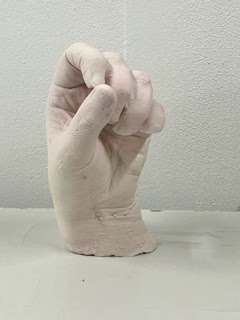

But, ALAS, I had managed to miss out some finger parts!

I guess I must have caught some air as I pushed my hand in.

I did get my hand into the position I wanted before pushing it into the alginate – on reflection I should have pushed my hand in open, then formed the shape I think.

I shall have another go and test that theory.

But it was good to have a go,

and discover what errors can be made..... and changed in the future.