The last largish thing I planned to

build for the mini shed was a table. Having

already made a smaller mosaic table, I needed a larger table to go with the

bench. Somewhere where mini people could

work 😊

I am a bit more confident with my

woodworking skills now so I thought this would be a piece of cake.

I cut up some dowel for legs and

found a square bit of wood in the scrap box – perfect! The scale worked well with my mini bench.

Having

learnt from working on previous parts of the mini shed, it is beneficial to drill

a small hole first for your screw to grip onto. So I drilled into the top of

the leg and through the table top.

But,

then I thought about how the screw would be sticking out of the top of the

table. How could I sink it? It’s called

‘countersinking’ I have since found out with the aid of Google. So with a larger drill bit I drilled a

slightly larger hole, just a couple of millimetres down, so that the screw head

would be below the top of the table.

Then I screwed the legs onto the

table. Not hugely straight mind you, but

at least there was no wobble.

Now

I had to deal with the holes on the top of the table so I could have a nice smooth

surface. I didn’t have any wood filler

so I used a blob of wood glue. It worked quite well luckily.

The next step was to smarten it up

a bit. I decided to do some Napkin Decoupage on the top, but first I would need

a coat of paint. I used a basic white

acrylic to give it an undercoat.

Then I painted the underside of the

table and the legs in a couple of coats of metallic brown acrylic, to match the

mini bench I had just finished.

Once that was all dry I could add

the napkin to the table top.

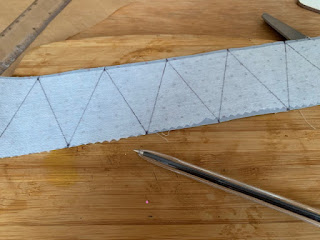

Napkin Decoupage is a lovely craft,

and you can put your napkin onto all sorts of things like glass bottles and slate

coasters. First of all you have to separate

the napkin plys – these are the layers of paper within the napkin. There are

usually three, occasionally four. You

need only to use one single ply with the pattern on.

Having

separated the plys, I then coated the table top with Mod Podge – this is a glue

brand with a good formula that works really well with napkin decoupage, but PVA

glue can work just as well.

Once coated I then laid the singly

ply napkin down on the top and with a piece of cling film wrapped around my finger

I smoothed out all of the wrinkles. Stupidly

I pressed too hard at this stage (you do have to be quite gentle) and took some

of the napkin back off, so I had to strip it back off. I was very annoyed with myself for being so

careless. The now took me back a couple

of steps as I then had to repaint the table top!

The

second attempt went much better as I was extra careful with my smoothing out. Once the napkin was in place I gave it

another coat of Mod Podge and left it to try before trimming the excess napkin

away.

And

that is my little table finished. The

top is very scuff proof thanks to the Mod Podge top coat and I think it looks

rather good(even if it does have a wonky leg!!)

This

mini table took me around two hours to make in total, not including drying

time. so my whole mini shed project is

now up to 44 hours in total.

If you would like to have a go at Napkin Decoupage, then have a look at my YouTube Tutorial on how to do a flat slate HERE or a bottle HERE.